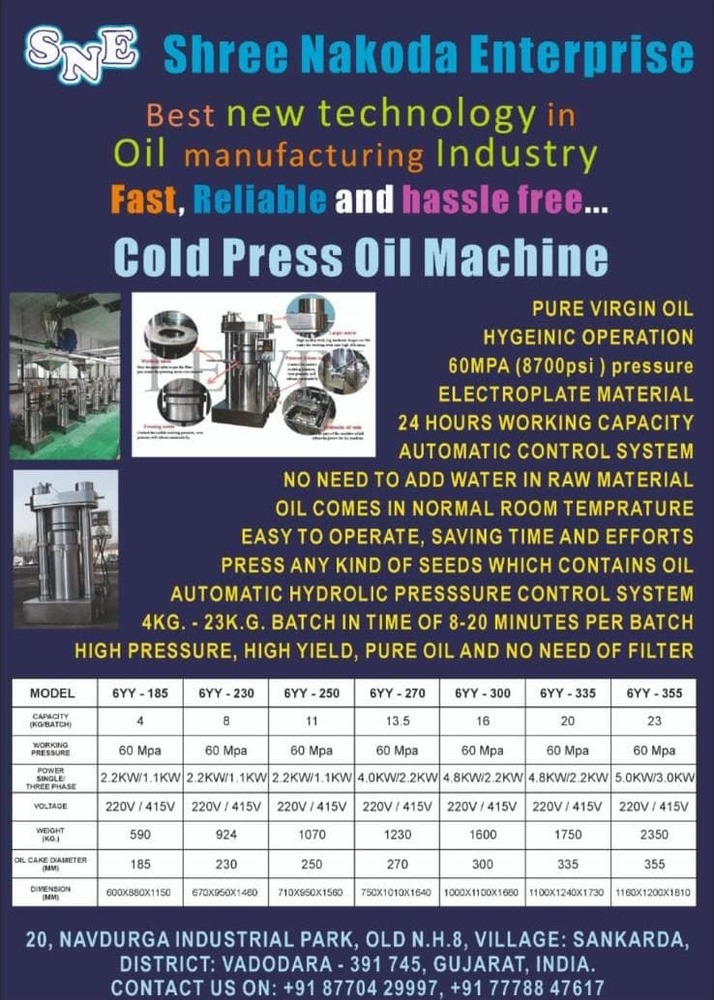

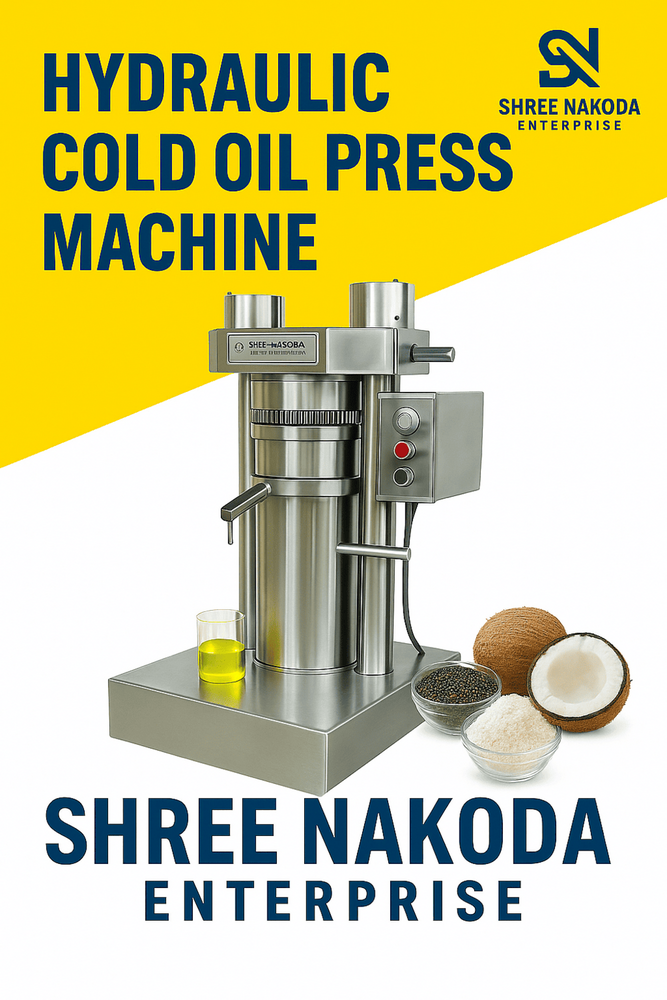

Chia Seeds Hydraulic Cold Oil Press Machine

580000 INR/Number

Product Details:

- Nominal Force 60 Tons

- Power Source Electric

- Condition New

- Dimension (L*W*H) 950 mm x 1200 mm x 1800 mm

- Power(W) 3 kW

- Voltage 380V/50Hz

- Motor Hydraulic Motor

- Click to View more

X

Chia Seeds Hydraulic Cold Oil Press Machine Price And Quantity

- 340000.00 - 870000.00 INR/Number

- 1 Number

- 580000 INR/Number

Chia Seeds Hydraulic Cold Oil Press Machine Product Specifications

- Included

- 950 mm x 1200 mm x 1800 mm

- 3 kW

- 550 mm x 650 mm

- 380V/50Hz

- 700 mm

- Equipped

- Electric

- 60 Tons

- Available

- Yes

- New

- Installed

- Hydraulic Motor

Product Description

Advantage:

- This hydraulic oil press machine is the most advanced equipment and takes up less area. Its material mainly electroplate.

- It is economic and environmental protection, stable and durable. This machine adopts automatic control system, hydraulic pressure control system and temperature control system.

- It has high pressure, high yield oil and easy to operate.

Superior Cold Press Technology

Equipped with hydraulic cold press extraction, this machine ensures nutrient-rich oil from chia seeds, flaxseed, sesame seeds, and more. The cold press method preserves antioxidants and essential fatty acids, making the extracted oil healthier and more valuable for culinary and cosmetic uses.

Intelligent Automation and Enhanced Efficiency

Featuring a modern PLC touch screen, operation is streamlined and highly customizable. The automatic control system boosts productivity while reducing operator involvement, ensuring consistent oil output rates of up to 60 kg/h and minimized residue loss.

Robust Construction and Minimal Maintenance

With a sturdy frame made from high-grade steel, the machine is engineered for longevity and stable performance under continuous operation. The hydraulic system and essential safety components, including pressure gauges and valves, enable dependable, low-noise function with reduced wear and tear.

FAQ's of Chia Seeds Hydraulic Cold Oil Press Machine:

Q: How does the cold press process benefit oil extraction from chia seeds?

A: The cold press process ensures oil is extracted at lower temperatures, preserving vital nutrients, antioxidants, and healthy fats in chia, flaxseed, and sesame oil. This method produces high-quality oil without chemical additives or excessive heat, suitable for both consumption and cosmetic applications.Q: What types of raw materials can this oil press handle besides chia seeds?

A: In addition to chia seeds, the hydraulic cold oil press is designed to process a variety of seeds, including flaxseed and sesame seeds. Its adaptable construction makes it compatible with other oil-rich seeds, enhancing versatility for producers.Q: When should the oil press machine be maintained to ensure optimal performance?

A: Regular maintenance is recommended after consistent use, typically following each large batch or at least once a month, depending on the working hours and intensity. Simple cleaning and periodic checks of hydraulic components, seals, and the PLC system help maintain efficiency and longevity.Q: Where can this cold oil press be installed and operated?

A: This machine is suitable for installation in oil-producing facilities, farms, commercial kitchens, or small-scale processing units. Thanks to its robust build and relatively compact size, it fits well in dedicated industrial spaces or commercial production lines.Q: What are the benefits of the automated PLC touch screen control system?

A: The PLC touch screen simplifies operation by allowing easy monitoring, adjustment, and automation of oil extraction parameters. It enhances precision, reduces manual errors, and streamlines the process for consistent, high-yield output.Q: How much noise does the machine generate during oil extraction?

A: Engineered with a low-noise hydraulic system, the machine operates quietly, making it well-suited for environments where noise reduction is important, such as urban manufacturing plants or indoor facilities.Q: What steps are involved in using the machine for oil extraction?

A: Operation involves loading cleaned seeds into the press, selecting parameters via the PLC touch screen, and starting the hydraulic extraction process. The machine automatically applies the set pressure, extracts oil, and collects residue-all while monitoring output for efficiency and low residue oil rates.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email