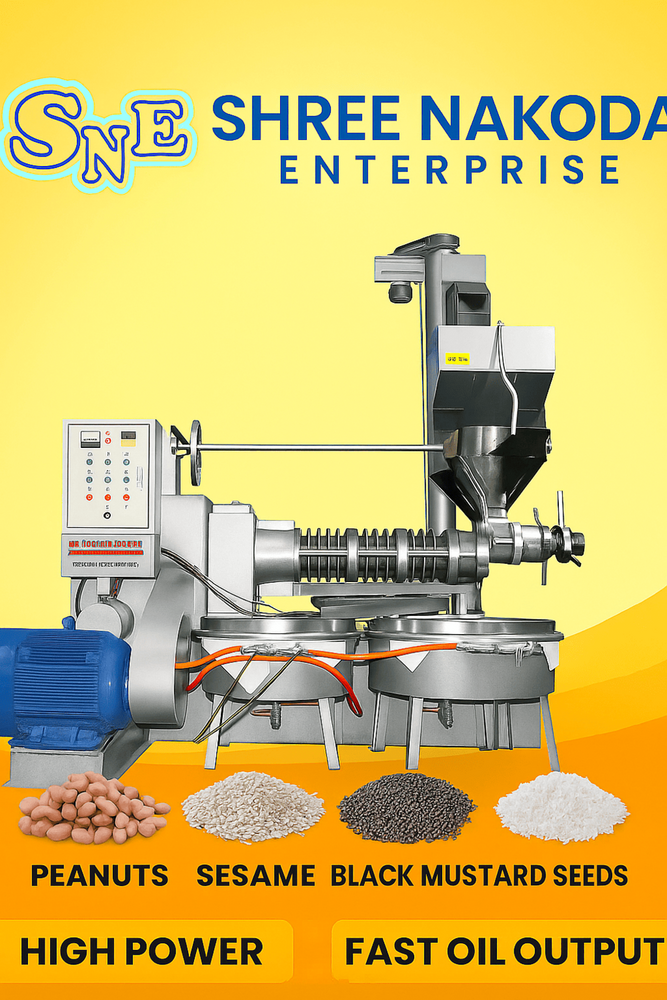

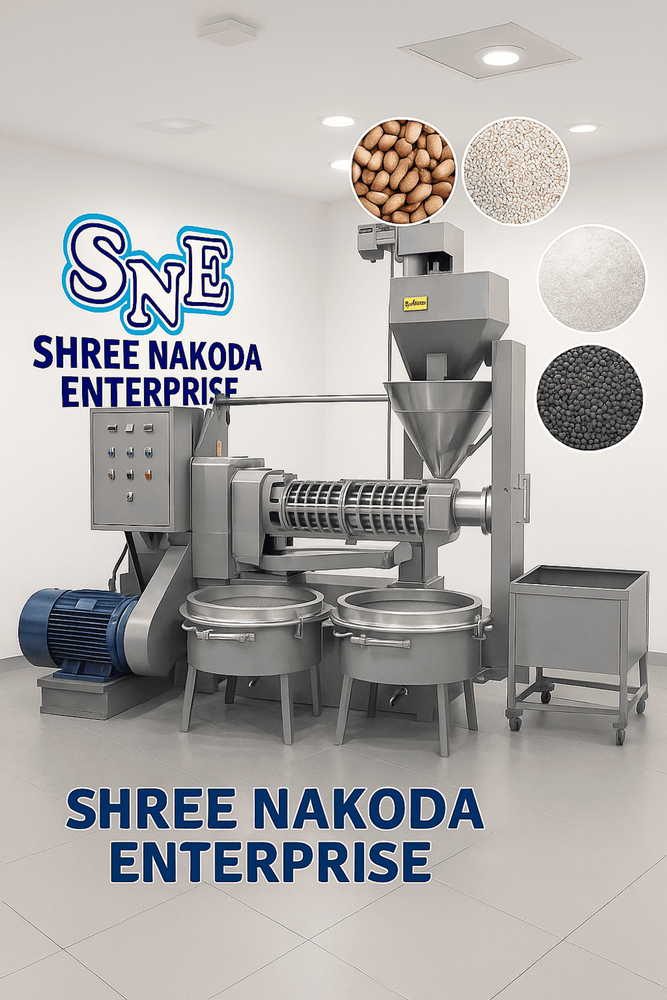

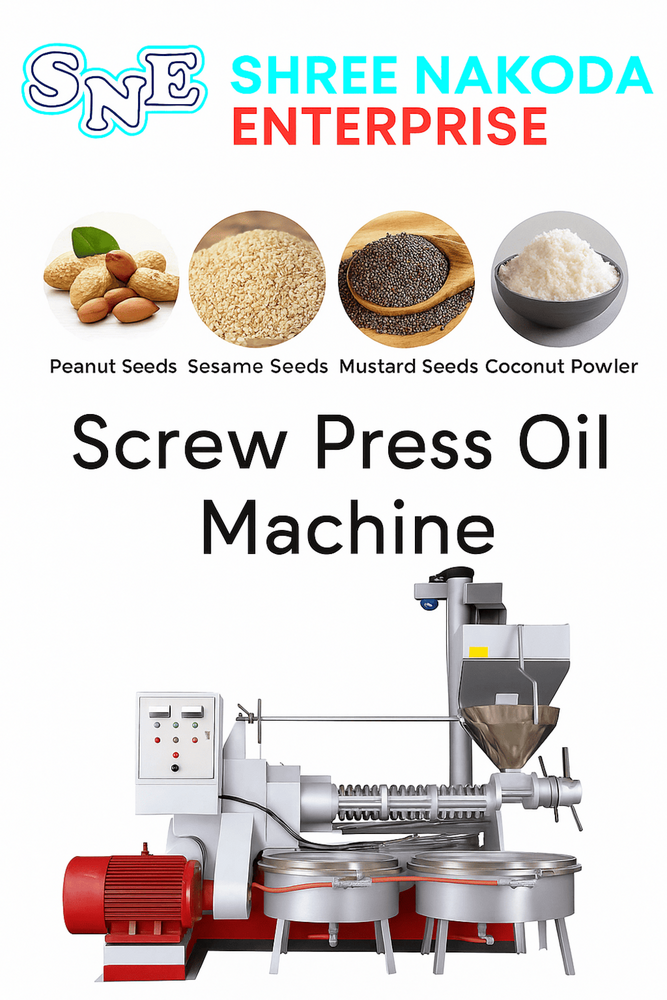

Mustard Screw Press Oil Machine

1110000.00 INR/Plant

Product Details:

- Production Capacity 2 Ton/day

- Automatic Grade Automatic

- Weight (kg) 1600 Kilograms (kg)

- Color Silver

- Warranty 1 YEAR ELECTRICAL PARTS

- Click to View more

X

Mustard Screw Press Oil Machine Price And Quantity

- 600000.00 - 1100000.00 INR/Plant

- 1 Plant

- 1110000.00 INR/Plant

Mustard Screw Press Oil Machine Product Specifications

- 1 YEAR ELECTRICAL PARTS

- Automatic

- 2 Ton/day

- Silver

- 1600 Kilograms (kg)

Mustard Screw Press Oil Machine Trade Information

- 1 Plant Per Month

- 30 Days

- All India

Product Description

Features and Advantages :

- Electromechanical integration, advanced technology

- Pure copper motor, strong stability.

- Vacuum oil filter system, get pure oil.

- 130r min, high oil yield

- L-type feeding system, avoid oil waste.

Brief Instruction :

- Our screw model oil press machine can do both hot and cold press, protect the quality of the oil.

- This oil press machine can work with many different oil material and it can be set different temperature for different material, high working efficiency and high oil yield.

- Vacuum oil filter service the oilpress machine well, can get the oil at the food grade level directly.

- We equipped the L type oil cake feeding system, just need one worker to operate it,save labour and improved the working efficiency.

- The thickness of the oil cake can be adjusted according to the request.

Working Principle :

- Screw oil press machine is specially for cold and hot press. The material was push by the press screw and squeezing during the pushing by the different capacity of the press kettle, the oil will discharge from the space of the cage bar or the oil pocket. After the vacuum oil filter, the quality of the oil can be reached to the cooking grade.

Application range :

- This machine can press a variety of raw kinds, including peanut, rapeseed, sunflower, soybean, flax, walnut and other oil craps.

Advantages:

- It is economic and environmental protection, stable and durable performance. In addition, It is high pressure, high yield oil, oil pure and fragrant.

- Gear transmission with low noise and smooth.

- Use excellent heat treatment equipment, the press parts wear-resistant, The temperature of the oil is automatically temperature controlled to improve the processing speed of the oil, and the low temperature environment can be produced normally.

- The infrared heating preheating temperature can be controlled to set the heating system, and the press can be pressed at the start.

- The oil filter is dense so that the oil can be filtered clean.

- This machine can work continuously for 24 hours. The life of this machine is ten years or longer.

- The diameter of the spiral squeezer is longer than other similar products.

- The main components of our machines are produced by ourselves in order to guarantee the oil rate and the quality of the machine.

Technical Specification :

Model

6YL-120

Capacity (kg/h)

120-160

Power (Kw)

15

Vacuum Power (Kw)

1.1

Voltage

415V

Weight(kg)

1500

Squeezer speed(rpm)

100-130

Size (m)

2*1.6*2.7

Automated Precision & High Production

Equipped with an advanced PLC control system, the Mustard Screw Press Oil Machine ensures automated operation and consistent output quality. Its powerful motor range and large weight capacity enable it to produce up to 700 kg of oil per hour, making it suitable for industrial-scale applications where efficiency and reliability are essential.

Durable Build and Reliable Warranty

Constructed from stainless steel, this machine is engineered for long-term durability and resistance to wear. The included 1-year warranty covers all components, including electrical parts, providing users with peace of mind and support throughout the first year of operation.

FAQs of Mustard Screw Press Oil Machine:

Q: How does the Mustard Screw Press Oil Machine operate?

A: This machine uses a screw pressing mechanism to extract oil from mustard seeds. Its automatic system, managed by PLC control, ensures precise and efficient oil pressing with minimal manual intervention.Q: What is the production capacity of this oil press machine?

A: The production capacity varies from 100 to 700 kilograms per hour, or up to 2 tons per day, depending on operational settings and the specific model used.Q: When should I perform maintenance on this machine?

A: Regular maintenance is recommended every few weeks, focusing on inspecting the screw press mechanism, cleaning the stainless steel parts, and ensuring the electrical components are functioning correctly.Q: Where is the Mustard Screw Press Oil Machine commonly used?

A: This oil press is primarily utilized by manufacturers, suppliers, and oil processing units across India, particularly where large-scale, automatic operations are required.Q: What are the advantages of choosing a stainless steel (SS) construction?

A: Stainless steel material ensures durability, resistance to corrosion, and compliance with food industry standards, making the machine suitable for continuous industrial use.Q: How do I benefit from the PLC control system in this machine?

A: The PLC control system allows for enhanced automation, greater consistency in production quality, and easier troubleshooting, optimizing your workflow for higher output and reduced downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email